Global Manufacturing Solutions

Electric Vehicle Powertrain and Global Supply Chain

Exploded View of Vehicle Chassis and Drivetrain

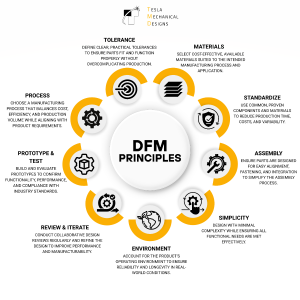

Tesla Mechanical Designs – DFM Core Principals

Tesla Mechanical Designs – Where Design Meets Innovation

Firm’s rigorous DFM and production-ready documentation empower clients to build agile, resilient, and geographically diverse manufacturing networks.

— Prex Poojara, Director at Tesla Mechanical Designs

CO, UNITED STATES, September 12, 2025 /EINPresswire.com/ — As global industries continue to navigate supply chain volatility, Tesla Mechanical Designs is delivering a powerful solution through its core engineering principles. The firm’s deep focus on Design for Manufacturability (DFM) and the creation of pristine technical documentation provides clients with the ultimate tool for agility: a truly portable design. By offering expert Mechanical Design Services that prioritize clarity and producibility across the entire Product Development lifecycle, The Engineering firm empowers companies to de-risk their supply chains, seamlessly onboard new manufacturing partners, and ensure consistent quality across any production facility in the world.

𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐢𝐧𝐠 𝐟𝐨𝐫 𝐚 𝐍𝐞𝐰 𝐄𝐫𝐚 𝐨𝐟 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠

Recent global disruptions have exposed the vulnerabilities of lean, geographically concentrated supply chains. In response, a major strategic shift is underway, with companies now prioritizing resilience and flexibility. The challenge for many in Custom Manufacturing is that moving production or qualifying a new supplier is often hampered by poor documentation, overly complex designs, or processes tied to a single vendor’s specific capabilities.

Tesla Mechanical Designs addresses this fundamental challenge by embedding portability into every stage of the design process. The firm operates on the principle that a well-engineered product should not be constrained by its original manufacturing plan. Instead, its design data from 3D models should serve as a universal blueprint that enables high-quality production anywhere, anytime.

“We engineer for manufacturability, creating clear, robust, and universally design packages. This frees our clients from dependency on a single factory or region, transforming their product design into a strategic asset for business continuity,” says Kuldeep Gajjar, director at Tesla Mechanical Designs.

𝐓𝐡𝐞 𝐏𝐢𝐥𝐥𝐚𝐫𝐬 𝐨𝐟 𝐚 𝐓𝐫𝐚𝐧𝐬𝐟𝐞𝐫𝐚𝐛𝐥𝐞 𝐚𝐧𝐝 𝐑𝐞𝐬𝐢𝐥𝐢𝐞𝐧𝐭 𝐃𝐞𝐬𝐢𝐠𝐧

Tesla Mechanical Designs’ approach is built on a foundation of core engineering services that directly contribute to supply chain resilience:

1. Intensive Design for Manufacturability (DFM): At the heart of their process, DFM simplifies and standardizes parts for ease of production, applying Lean Manufacturing principles. By optimizing Mechanical Component Design and leveraging expert Component Engineering, the firm ensures that products can be built efficiently by a wide range of suppliers, not just a select few.

2. Impeccable Technical Documentation: Tesla Mechanical Designs elevates its Mechanical Drafting Services to a strategic level. The team produces exceptionally clear and comprehensive Mechanical Drawings and models. This precise CAD Drafting eliminates ambiguity, reduces the risk of errors during production transfer, and dramatically shortens the learning curve for new vendors, and generates the necessary technical documentation for various global certifications.

3. Strategic Material and Process Selection: During the Product Development cycle, the team advises clients on using widely available materials and standard production methods for any Custom Component Design. This proactive guidance avoids reliance on niche, single-source suppliers and mitigates potential supply chain bottlenecks across all Manufacturing Services.

𝐄𝐧𝐚𝐛𝐥𝐢𝐧𝐠 𝐀𝐠𝐢𝐥𝐢𝐭𝐲 𝐰𝐢𝐭𝐡 𝐑𝐞𝐯𝐞𝐫𝐬𝐞 𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐢𝐧𝐠

For companies looking to diversify their sourcing for existing products, Tesla Mechanical Designs offers powerful Reverse Engineering Services. The team can take a physical component—even one without existing documentation—and perform 3D Reverse Engineering to create a complete, production-ready digital data package. This CAD Reverse Engineering empowers clients to break free from single-supplier dependencies and source critical parts from a competitive and diverse global market.

By partnering with Tesla Mechanical Designs, organizations gain a powerful strategic advantage. They are equipped with the high-quality engineering data needed to build a robust, flexible, and truly global manufacturing footprint, ensuring business continuity in a volatile world. With a vast vendor network spanning the globe, Tesla is well-equipped to support your production needs. Our vendor selection process is highly stringent and involves multiple levels of validation. Consequently, the vendors we partner with adhere to the highest engineering practices and comply with global standards.

𝐀𝐛𝐨𝐮𝐭 𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧𝐬

Tesla Mechanical Designs is a premier engineering solutions provider dedicated to transforming innovative ideas into market-ready products. The firm combines a legacy of precision with a forward-thinking approach to product development. Its team of seasoned engineers and designers acts as a strategic extension of its clients’ teams, offering deep expertise across the entire design-to-manufacturing lifecycle. The company’s mission is to deliver exceptional value through collaborative partnerships, technical excellence, and an unwavering commitment to client success.

Divya Dave

Tesla Mechanical Designs

+1 214-699-6163

email us here

Visit us on social media:

LinkedIn

Bluesky

Instagram

Facebook

X

Legal Disclaimer:

EIN Presswire provides this news content “as is” without warranty of any kind. We do not accept any responsibility or liability

for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this

article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

![]()

Article originally published on www.einpresswire.com as Tesla Mechanical Designs Fortifies Global Supply Chains with Manufacturability-Focused Engineering